The Fastest delivery ability of high precision PCB manufacturer !

PCB & Assembly Services

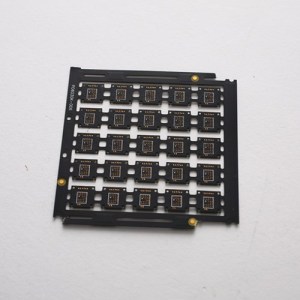

PCBQuick provides turnkey PCB assembly services for prototype or small to medium production runs.We handle the whole process including: ordering all components, PCB manufacturing, PCB assembly, testing and final shipment.We can assemble BGA, Micro-BGA, QFN and other lead-free packaging parts.

Flex-rigid PCB Manufacturing

PCBQuick provides rigid-flex printed circuit boards in various standard and custom specifications for 3 layer Flex-Rigid PCB to 14layer flex-rigid PCB. These printed circuit boards are used regularly in industries such as power, automobile, telecommunication and lighting. Flex-rigid PCB boards are multilayer boards using flexible polyimide on the part of the product and fiberglass.

Rigid PCB Manufacturing

Flexible PCB Manufacturing

Compared with rigid PCB, flexible PCB has many advantages, light, thin, small, more reliable, low cost, Flexible Circuit Board are widely used in many fields, like automotive electronics, communication equipment, laptop, smartphone etc. electronic products.flexible pcb manufacturer in China, ShenZhen KingFung technology Co, LTD.We have 15 years of production experience, PI Material Flexible PCB, Printed Circuit Board and FPC Board can meet the needs of customers.

Aluminum PCB Manufacturing

Aluminium printed circuit boards are used for the thermal management of the circuit. The Solution to High power LEDs, parts for controls, power transducers etc. are often developed with metal core PCBs. Aluminum PCB commonly used in Led PCB Board, LED Light Circuit Board, LED Display PCB Board, Aluminum Based LED PCB, OSP LED PCB. Presently we offer aluminium core printed circuit boards with the following technology: 0.8, 1.0, 1.2, 1.5, 2.0 mm thicknessIsolation layer: 75-100µmCopper: 18, 35, 70 µm Cu single sided or double sideGet a quotation to buy@pcbquick.com

PCB Copy & PCB Design

PCB copy board/change board (Electronic product clone), PCB backward reasoning/schematic diagram making,SMT/PCBA processing, PCB prototype/batch production, Batch component matching procurement, BOM analysis and making, Functional prototype manufacturing and test, Difficult component/module substitution, Chip decryption and program analysis, IC reverse design, Chip failure analysis, Chip codepoint extraction and copy, OEM/ODM of various finished products & semi-finished products

PCB Laser Stencil

- Name:

- Mary

- Tel:

86-0755-29518736

- Email:

- mary@kfquickpcb.com

- WhatsApp:

- https://wa.me/8613632989860

- Skype:

- Skype:pcbquick

- Address:

- Building D, Xintai Industrial Park, Xitou Second Industrial Zone, SongGang Town,Bao'an,Shenzhen,China

- *Title

- *Content

Focus on mobile phone clients