The Fastest delivery ability of high precision PCB manufacturer !

Language:

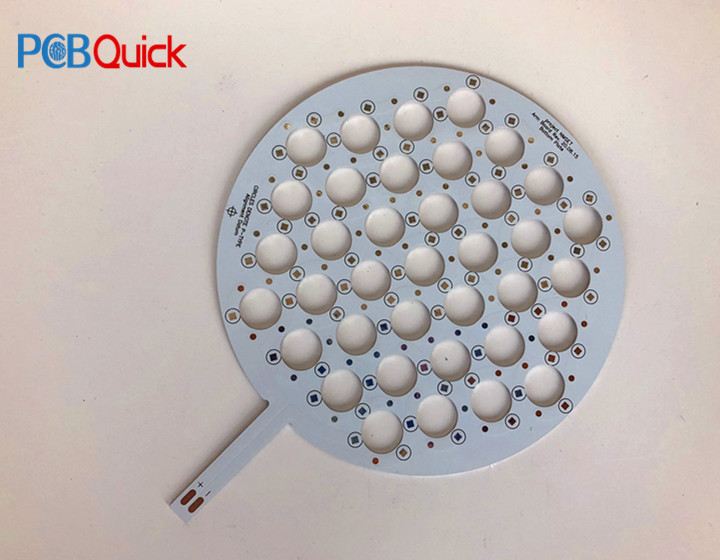

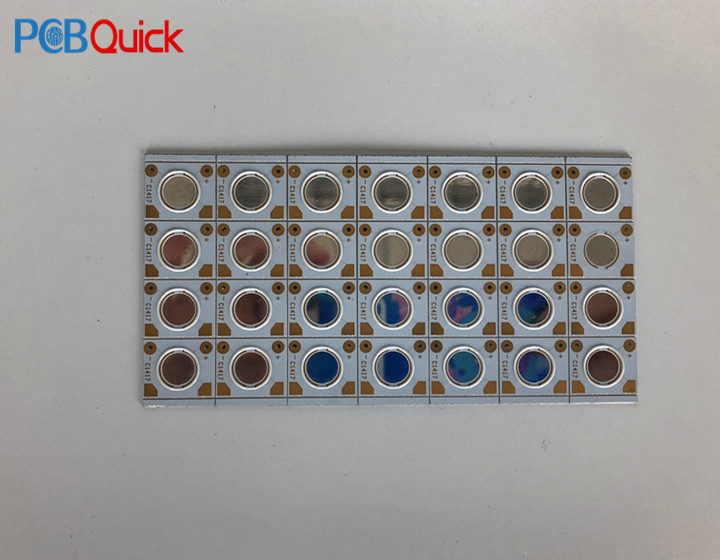

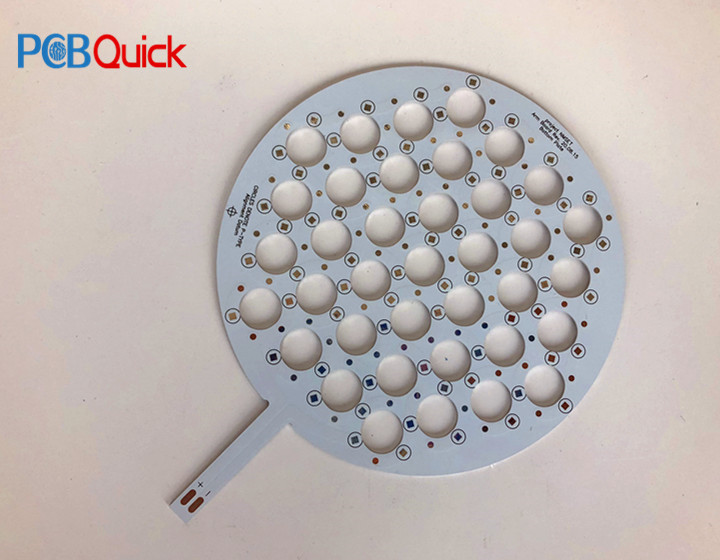

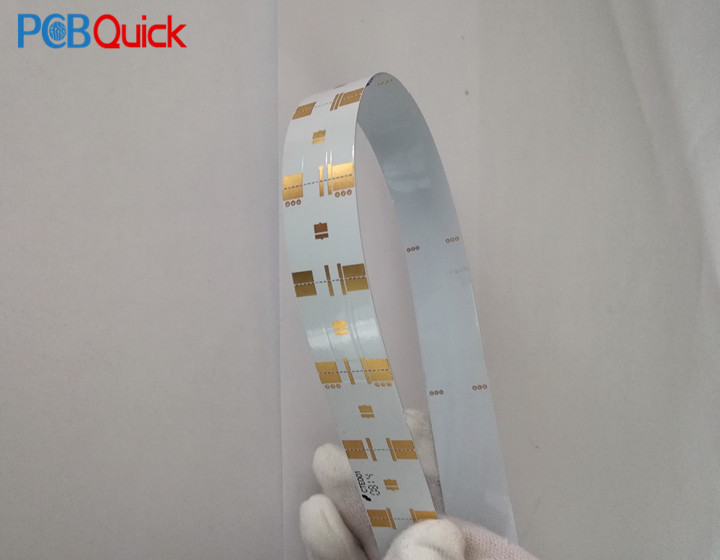

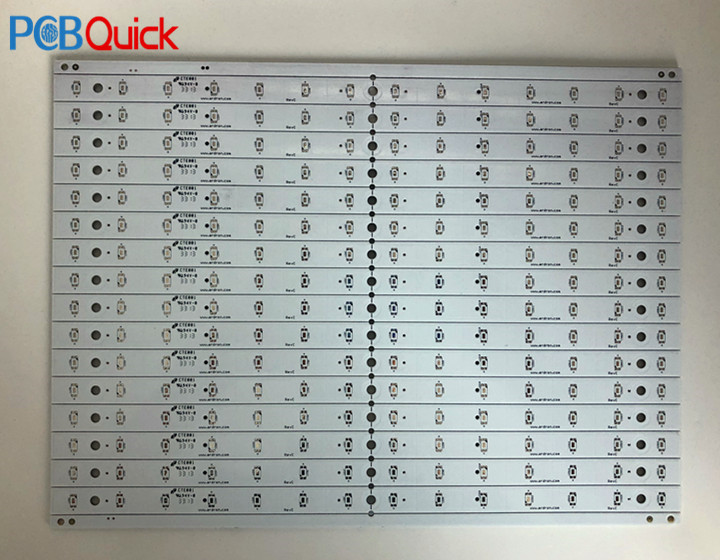

Home / Aluminum PCB

CONTACT US

- Name:

- Mary

- Tel:

86-0755-29518736

- Email:

- mary@kfquickpcb.com

- WhatsApp:

- https://wa.me/8613632989860

- Skype:

- Skype:pcbquick

- Address:

- Building D, Xintai Industrial Park, Xitou Second Industrial Zone, SongGang Town,Bao'an,Shenzhen,China

FOLLOW US

Please send your message to us

- *Title

- *Content

MOBILE WEB

Focus on mobile phone clients

QR code

subscription