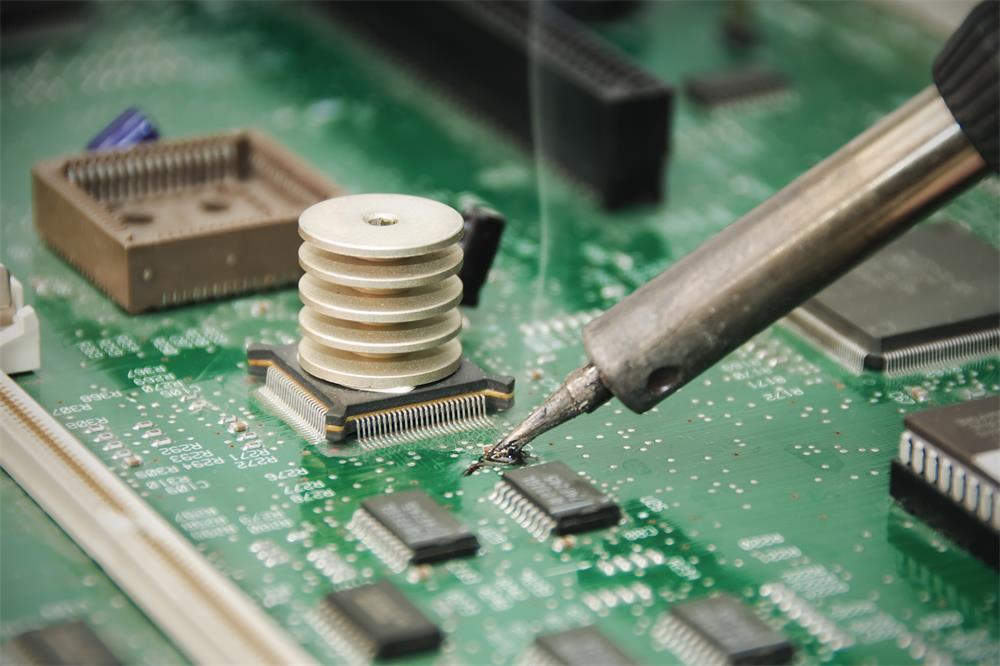

Soldering Process of Printed Circuit Boards(PCBs)

Printed circuit board soldering is to solder the wires together by soldering the components to form a complete circuit to meet its corresponding functions. The soldering of printed circuit boards has many points that need attention, the following is the soldering process of printed circuit boards.

1. Preparation before welding

First, be familiar with the assembly drawing of the printed circuit board to be welded, and prepare the ingredients according to the drawing, check whether the model, specification, and quantity of the components meet the requirements of the drawing, and make preparations for the lead forming of the components before assembly.

2. Welding sequence

The order of assembly and welding of components is: resistors, capacitors, diodes, transistors, integrated circuits, high-power tubes, and other components are small first and then large.

3. Requirements for welding components

(1) Resistor welding

Install the resistor in the specified position according to the figure. The mark is required to be upward and the word direction is consistent. After installing the same specification, install another specification, and try to make the height of the resistor consistent. After soldering, cut off all the excess pins exposed on the surface of the printed circuit board.

(2) Capacitor welding

Install the capacitor in the specified position according to the figure, and pay attention to the polarity of the "+" and "-" poles of the polarized capacitors, and the direction of the mark on the capacitor should be easy to see. Install glass glaze capacitors, organic dielectric capacitors, and ceramic capacitors first, and finally install electrolytic capacitors.

(3) Welding of diodes

Pay attention to the following points in diode welding: first, pay attention to the polarity of the anode and cathode, and not install it wrong; second, the model mark should be easy to see and visible; third, when welding a vertical diode, the shortest lead welding time cannot exceed 2 seconds.

(4) Triode welding

Note that the e, b, and c three leads are inserted correctly; the welding time is as short as possible, and the lead pins are clamped with tweezers during welding to facilitate heat dissipation. When welding high-power transistors, if you need to install a heat sink, the contact surface should be flat and smooth before tightening. If you need to add an insulating film, do not forget to add a film. When connecting the pins to the circuit board, use plastic wires.

(5) Integrated circuit welding

First, check whether the model and pin position meet the requirements according to the requirements of the drawing. When soldering, solder the two pins on the edge first to position them, and then solder them one by one from left to right from top to bottom.

The function of electronic products depends on the correct interconnection of electronic components, and most of the connections of these components are realized by the welding of printed circuit boards, so we need to pay more attention to the entire welding process. If you want to learn more about printed circuit boards after reading the above, you can contact us for detailed and comprehensive solutions.

As a professional PCB product manufacturer, we have rich manufacturing experience and leading R&D technology in this field. We always produce in accordance with strict standards and have established a complete quality inspection system to provide customers with high-quality and safe products. We also provide thoughtful after-sales service and good solutions. If you are interested in our printed circuit boards, please contact us immediately!